Having the job of producing an indefinite number of metal castings is not easy, but the requirements of the product can usually help determine which manufacturing process needs to be… [Continue Reading]

Category: Vacuumcasting

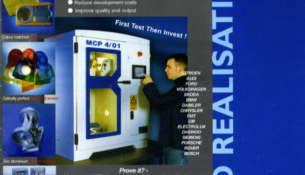

20.02.2004 – MCP Vacuum Casting: World wide the most widely used package process for producing plastic and wax prototype castings from Rapid Prototypes in as little as 12 hours! Produce prototypes from 1 gramm up to 15 kg.

Prototype parts in 24 hours

A new material for polypropylene simulation MCP-HEK has introduced a new vacuum resin, 8040, for vacuum casting, worldwide, the most commonly used process for producing quick, multiple prototypes from generatively… [Continue Reading]

One Step Ahead

A new Rapid Manufacturing Process for producing protototypes and production parts in Nylon – PA6. All the advantages of MCP Vacuum Casting Technology – only much quicker. Utilise all the time and cost… [Continue Reading]

MCP Supply Materialise in Leuven, Belgium

MCP supplies Materialise in Leuven, Belgium with one of the largest vacuum casting machines ever built. The machine will produce plastic and wax prototypes up to 13 kg in weight… [Continue Reading]

Further Publications from Ron Simmonds

Casting for Rapid Prototyping Sucess

Create prototypes in plastic and metal within hours with MCP Vacuum Casting Technologies. Elemente long delivery times for prototypes Reduce development costs Improve quality and output Original published in 2001

Image Gallery Vacuumcasting (Exemplary flow)

Please click to enlarge the Images.

Casting for success

HEK GmbH is a member company of the 60 year old MCP Group, one of the oldest producers of low melting alloys worldwide. Low melting alloys were traditionally used in… [Continue Reading]

HEK makes inroads with vacuum casting

Firms and educational organisations in Indonesia, Singapore and Malaysia are all catching on to German company HEK’s MCP-Vacuum Casting System for making highly accurate and durable prototype products. Original published… [Continue Reading]

Rapid prototype component production at Porsche

How Weissach engineers save 90 percent in costs and 95 percent in time. Original published in: Christopherus Porsche Magazin 2/96