1985: Cost and Time Saving The famous Porsche 959 used carbon fibre (CFK) body components produced with the MCP Metal Spray Mould technology. Approx. 350 Cars were produced

Category: Prototyping Museum

Metal Spraying with Low Melting Point Alloys

Metal spraying with low melting point alloys is a technical development that has many interesting aspects. A system has been developed to satisfy the ever-growing demand for quickly made low-cost… [Continue Reading]

MCP 70 hot wire cutting system

This system has been specifically designed to be used in conjunction with MCP 70 low melting point alloy for producing the shielding blocks required during radiation treatment. The system comprises a… [Continue Reading]

Systems of mould making für unit soles in PU foam

Published in SCHUHTECHNIK, Specialedition 6/75 in german and english language.

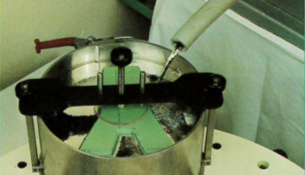

The MCP 70 MK III Hot Wire Cutting System

The MCP 70 MK III system meets the demand of treatment centres for greater accuracy in radiation shielding. Using a heated wire system enables accurate moulds to be cut from… [Continue Reading]

A Revolution in Radiation Treatment: Quick and Accurate Individual Patient Shields

1974: MCP 70 Technology for creating radiation shields rapidly : MCP introduced a rapid system , simple and effective ,afor producing individual shielding blocks for patient radiotherapy treatment. The advantages… [Continue Reading]

MCP introduce Metal Spray

The hardening of aluminium alloys by inclusion of small additions of bismuth and lead is rapidly increasing. To enable such additions to be made easily and accurately Mining & Chemical… [Continue Reading]