A combination of two prototyping technologies for producing high class pressure diecasting prototypes and pre-series requirements, can take as little as 24 hours to form complex wax and metal components.

Author: Ronald Simmonds

Dense, fast rapid tooling uses IR laser

A new selective laser melting rapid tooling machine allows production of 100 per cent dense metal parts from metal powder. Published in European Automotive Design in April 2003

Prototype Sheet Metal Forming

Tools and Parts with MCP 137 Low Melt Alloys published by MCP-HEK GmbH, Germany

Cool Spray Mouldmaking

MCP/TAFA makes a wide range line of energy-efficient thermal spray coating systems for a wide spectrum of industries. Everything from manually operated units to a totally automatic turnkey systems are… [Continue Reading]

MCP Supply Materialise in Leuven, Belgium

MCP supplies Materialise in Leuven, Belgium with one of the largest vacuum casting machines ever built. The machine will produce plastic and wax prototypes up to 13 kg in weight… [Continue Reading]

Generative Tooling Process

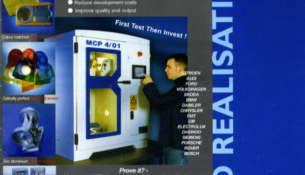

MCP-HEK of the MCP Group has announced exclusive sales rights for the MCP RealizerSLM – SLM initially developed by F + S Germany. The new laser-operated generative process will melt… [Continue Reading]

Further Publications from Ron Simmonds

Casting for Rapid Prototyping Sucess

Create prototypes in plastic and metal within hours with MCP Vacuum Casting Technologies. Elemente long delivery times for prototypes Reduce development costs Improve quality and output Original published in 2001

Overview Metal Sprayed Moulds (Exemplary flow)

Please click to enlarge the Images.

Image Gallery Vacuumcasting (Exemplary flow)

Please click to enlarge the Images.